Smart pharma

The digital transformation is impacting every manufacture, and pharmaceuticals are no exception. With some of the most stringent quality regulations to follow, the pharmaceutical industry faces unique challenges for which smart manufacturing offers promising solutions. When the starting signal is a brownfield site with aging infrastructure and digitally isolated legacy systems, implementing the necessary connectivity can exist a major hurdle. With its Orange Box solution, B&R offers an hands managable style to get brownfield sites connected and ready for the digital hereafter.

With the arrival of Industry 4.0 in the pharmaceutical industry, traditionally human-driven processes are becoming increasingly digitized and automated. The information that is generated allows for faster and ameliorate-informed decisions. Information technology allows problems to be predicted and corrected before they result in costly downtime or faulty products that could damage the manufacturer'due south reputation. Digitalized, fully integrated operations are more adaptive and responsive. They allow better utilization of raw materials, and increase both producivity and quality.

Nonetheless even with the many benefits these advancements offer pharmaceutical manufacturers, they too come with their share of new challenges. Among the about common concerns is the unknown cost of upgrading legacy equipment. For many factories with isolated islands of automation, a further challenge is how to achieve seamless advice both auto-to-machine and machine-to-cloud. And even with a shop flooring that is connected both horizontally and vertically, the side by side challenge is how to process and secure the flood of new data that is generated. Pharmaceutical companies need innovative means to mitigate these risks as they accept steps to leverage the benefits of the latest technology trends.

Retrofitting brownfield plants

Implementing smart manufacturing practices tin can seem an insurmountable challenge for brownfield plants with decades-old infrastructure. The time and toll involved in upgrading legacy systems, machines, devices and sensors acts as a major barrier to adoption of new technology. One specific challenge is how to collect plant-floor information and share information technology with higher-level control and IT systems.

Every bit a way to permit brownfield plants to outset enjoying the benefits of smart manufacutring with minimal capital letter investment and little modification, B&R developed the Orange Box. With it, users tin can hands access energy consumption and operating data from previously isolated machines and lines, making them Industrial IoT ready with minimal effort.

An Orangish Box tin can substantially reduce downtime and heave the availability of existing machines and lines, making operations more productive and assisting. Each Orange Box consists of a controller and preconfigured software components. The controller is able to collect operating information from any automobile via its I/O channels or a fieldbus connection. With this information, the software modules generate and display overall equipment effectiveness (OEE) and other KPIs, and tin can share this information with higher-level systems using open up source OPC UA or MQTT communication.

As simple and intuitive to use as a smartphone, the Orangish Box can be installed without any changes to existing hardware or software. Equipment owners tin can achieve a substantial boost in productivity with a remarkably minor investment in time and cost. The advanced free energy management office allows energy consumption to be measured directly on the machine and observed intuitively on the HMI screen. At a glance, operators tin encounter the energy consuption of individual devices or machines, or get an overview of the entire mill.

Secure data connectivity with OPC UA

As their store floors become increasingly continued, organizations face a whole new fix of security challenges. Pharmaceutical companies have highly sensitive intellectual belongings in the form of drug formulations and processing know-how that could be extremely damaging if compromised.

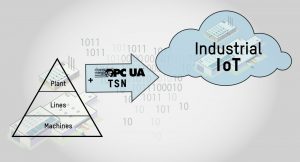

The OPC UA protocol offers platform and vendor-independent communication with built-in security mechanisms that go far the ideal solution to the cybersecurity challenge. With the recent addition of Time-Sensitive Networking (TSN), it at present offers secure, seamless, standardized communication all the mode from individual sensors and existent-time control systems up to ERP systems and the cloud.

A smart futurity

Despite its natural aversion to risk, the pharmaceuticals industry has slowly just steadily embraced its digital transformation. With the the Orange Box and OPC US over TSN, B&R is helping to remove the remaining hurdles and requite brownfield plants the connectivity and information analytics they need to benefit from the unprecedented productivity and profitability of smart manufacturing.

Operational excellence with collaborative robots

On the product floor, robots help eliminate homo mistake, increase accuracy and reproducibility, and remove the potential for human being contamination. In the laboratories used to develop and test new drugs, they are perfrect for performing repetitive, unskilled tasks such as blending, stirring and titration, allowing scientists to make better use of their education and know-how.

B&R'southward openROBOTICS seamlessly integrates robots into the motorcar control organization. New software features make it easier than e'er for car builders to synchronize robots with track-based transport systems and other dynamic machine components. Completely uniform programming for every component in the line has benefits from development and performance to diagnostics and maintenance. Together with B&R's SafeROBOTICS software package, human being operators tin can work safely shoulder-to-shoulder with robots without the restrictions of safety cages.

whisenanttere1995.blogspot.com

Source: https://packagingsouthasia.com/application/pharma/smart-pharma/

Post a Comment for "Smart pharma"